TELELIN INSTRUMENTS INDIA

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to TELELIN INSTRUMENTS INDIA

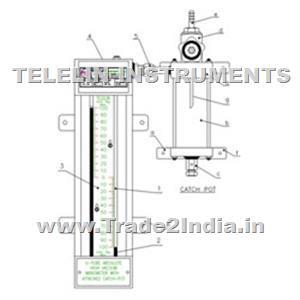

Orifice Assemblies

Orifice Plate with holding flanges nut bolts and gaskets are called orifice assembly. Flanges generally are of M.S. / C.S./304 S.S./ 316 S.S., nut bolts M.S. Galvanized, Gasket C.A.F. Other construction is possible & will be made against order. Flanges generally are of 4 types a) Weld Neck b) Slip-on c) Carrier Ring d) D & D/2 tappings or pipe run assembly. Pressure tappings are in flange itself in 1 st 3 types, while for D & D/2 they are on pipe. Assemblies supplied for 1½ “ to 24” Line sizes. Orifice bore calculations as per BS1042 on the basis of your given data is done & bore size is determined & made. Bore calculations are also provided alongwith instruments or can be sent for approval before manufacturing.

Orifice Plates

They are primary element to generate differential pressure for rate of flow measurement. Designed & made as per BS 1042, or as per your given drawing or dimensions.

Bore is precisely bored to exact tolerances & have sharp lead edge to ensure accuracy.

Line size i.e. exact I.D. & O.D. or pipe schedule, fluid data i.e. Name, Op. Temp., Op. Pressure, Maximum Flow details & Maximum D.P. at full flow details are required for making or quoting. Standard construction is 304 S.S. or 316 S.S. Any other construction is possible.

Standard thickness are 3 mm, 4.5mm, 6mm & 8mm .

For easy reference, Fluid, Flow, Bore & Line Size details are engraved on orifice plate handle.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.